This is an exciting refrigerator design project in collaboration with Arcelik AS in Turkey. We are introducing a new era of customizable home appliances, revolutionizing the way families interact with their refrigerators. Our stunning designs are meant to inspire and enhance the beauty of any home.

This project includes intensive market and technology research too. You can find the research report below.

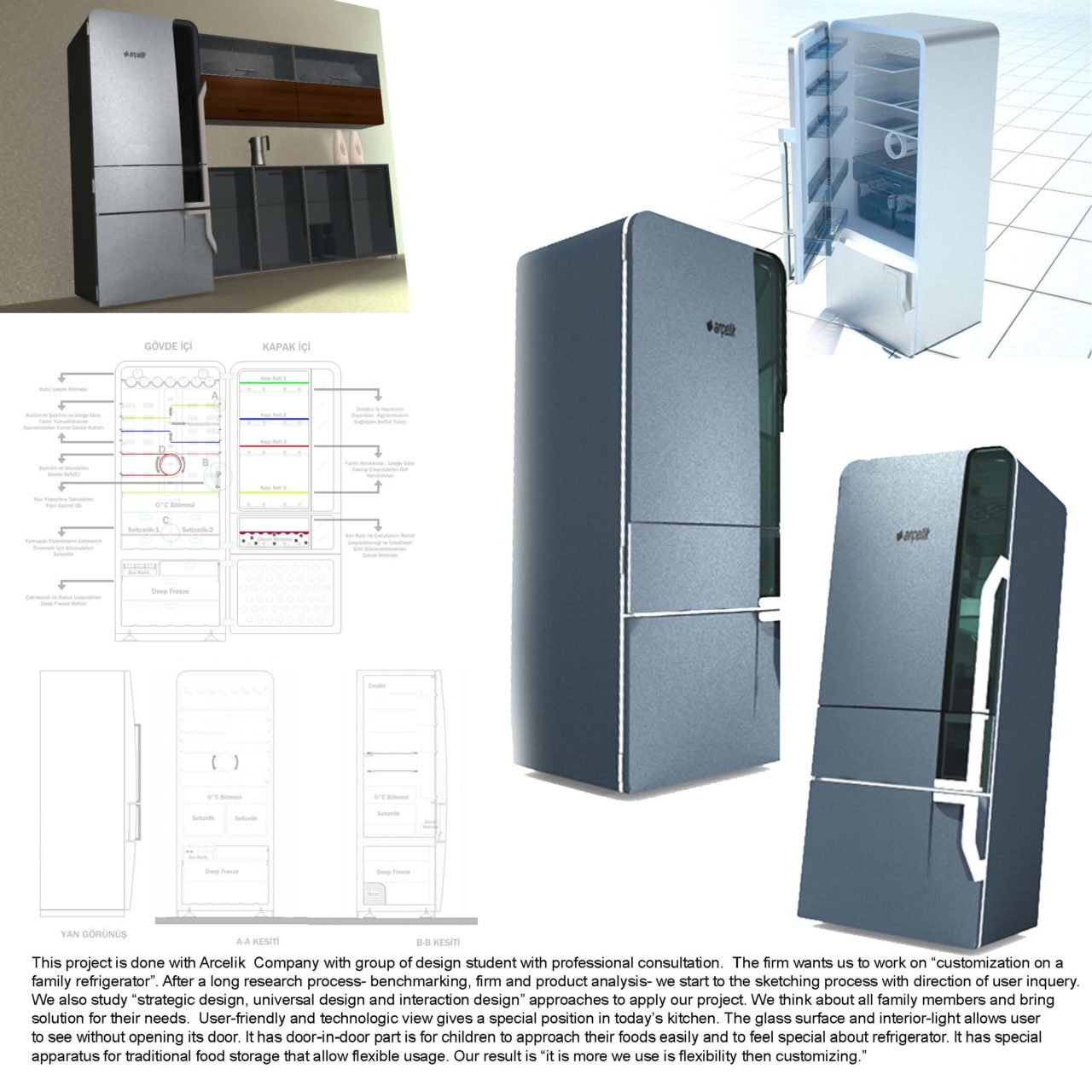

1:5 Scaled Model

DESIGN PROCESS AND INDUSTRY EXPERIENCE: ARCELIK- BEKO CASE PROJECT OF CUSTOMIZABILITY AND FLEXIBILITY OF A REFRIGERATOR

Abstract:

Designers often describe the design process as the conscious conversion of knowledge into tangible products or services. Design is not only the final object itself but also the process leading to its creation. Typically, the design problem is given to students by instructors in an educational setting, while in professional life, designers or industries identify the problem. This paper explains the design process of a refrigerator undertaken by master’s students from Anadolu University and the refrigerator department of Arcelik-Beko, one of the world’s largest white goods producers.

The project was executed with the master’s students, involving several meetings between the executives, students, and firm authorities. The first step was to identify the main problem and its subtopics, which proved challenging as it required a semi-real and semi-conceptual problem. A timeline was then established, and information flowed between the firm and students. Market information was provided by the firm and analyzed by the students, who also researched competitor firms and brands. Once the subject information was gathered, the sketching process began, with all sketches based on the collected data. Students aimed to transcend today’s technology, ensuring that the manufacturing knowledge guided the realization of the sketching lines. From hundreds of different ideas, a selection was made, and decisions were taken. For instance, the interior organization of the refrigerator was discussed based on frequency, and a special section was dedicated to children due to their role in shopping. Different colors and textures were experimented with on the refrigerator door. Final evaluations led to the creation of 3D animations, detailed technical drawings, and a 1/5 scale model of the product, which was presented.

Throughout the design process, there were mutual advantages shared by firm authorities and students. It was an educational and creative process for both parties, contributing to strengthening the collaboration between Anadolu University and Arcelik-Beko.

Design Process and Industry Experience:

Arcelik-Beko’s position within the sector:

The project began with a briefing from the firm and instructors, followed by meetings to understand the project’s scope and define the process. To gain insight into the firm, a visit to Arcelik-Beko was organized, providing students with a comprehensive understanding of the production and design processes and products. Additional information was gathered from local and foreign economic and marketing magazines, which were analyzed during the meetings.

Researching competitive trademarks in the sector:

The white goods sector is highly competitive, and Arcelik-Beko operates in a fiercely competitive state. Students researched domestic and foreign competitive trademarks, gathering articles and collecting products from other firms. A comparison was made across four market segments: one-door, double-door, no-frost, and side-by-side refrigerators. Various aspects such as volume, extra specifications, and price were evaluated, using data from the internet, product brochures, and sales points.

Academic Side:

Under the guidance of faculty instructors and the firm’s design chief, students embarked on an eight-month design marathon, complemented by academic courses related to sectoral design. Extra studies and research were conducted, exploring design approaches such as strategic design, universal design, and interactive design, which influenced the project’s outcome.

Marketing Research of Arcelik-Beko:

Arcelik presented the last marketing research findings, focusing on customer behaviors, customizability, and flexibility. These presentations further established the students’ research and expedited the research process. New user profiles were developed, and their demands and needs were studied through surveys, observations, and article research. The rapidly changing user profiles, especially among the new generation, influenced the design process.

Investigating the Refrigerator’s Interior:

Although all team members were users of refrigerators, they had never come so close to all parts of it. During a trip to the Arcelik-Beko firm, the team conducted a thorough examination of the refrigerators, inspecting each part in detail. Since the study was taking place at the university and it was difficult to access refrigerators when needed, the firm generously gifted one of the top models from each segment of their products to the team. This allowed the team to examine the refrigerators, their components, and systems more deeply, gain practical experience using them, and identify problems that customers faced.

Two Definitions: Customizability and Flexibility

The two concepts given for exploration were “Customizability” and “Flexibility.” One of the presentations from the firm focused on these concepts. Firstly, the team found the literal and connotative meanings of the concepts and defined the differences between “flexibility” and “customizability.” Secondly, they wrote down and discussed all the connotations associated with these concepts. They created mind maps and brainstormed ideas related to the concepts, the product, and its components. They explored questions such as “What can we do to make the product more flexible/customizable?” and “What can a flexible/customizable product do?”

Mind Maps and Brainstorming Results

As a result of brainstorming, mind mapping, and discussions, the team generated several ideas of what they could do. Some of the ideas included:

Diversity of colors

- Digital painting

- Double door

- Integrated shelves everywhere

- Modularity

- Jelly refrigerator

- Stoneware cooling

- Exterior lighting

- Paintable surfaces

- Exterior shelves

- Techno-gel shelves

- Diversity of forms

- Flexible shelves

- Mini bar

- Serviceable shelves

- Exterior illumination

- Cooling surfaces

- Direction of usage

- Sensitive shelves

- Electrostatic door

- Sketches on Ideas

The next step involved sketching and bringing the ideas to life. Each team member worked individually at the beginning, attempting to provide different solutions for the same ideas. All sketches were based on the collected data. The initial sketches were more conceptual, imaginative, and challenging to produce. Subsequently, the team selected the best sketches and ideas, which were then displayed on walls. After regular meetings with the instructor coach and firm designers, the ideas and sketches became more refined using known manufacturing techniques.

From Ideas to Reality

The user profile was defined as “a young family (possibly with one or two children).” Based on this profile, a probable refrigerator model was selected, and through further research, the volume and sizes were determined. This led to more detailed and appropriately sized designs. The individual study transformed into a group study, with a focus on one product. Some division of labor was established, and each group member took responsibility for specific parts of the product. It was challenging to maintain a consistent design language across all parts to create a cohesive design, so the team members met more frequently. Some decisions were modified during this process. For example, the shelf system initially planned to be flexible and usable, but it caused significant volume reduction when building a 1/10 scale model. As a result, it was changed to half shelves, while still maintaining flexibility.

After the final evaluations, 3D animations, details, and technical drawings were created. A 1/5 scale model of the refrigerator was constructed using original materials for the model parts, resulting in a realistic appearance. A presentation was conducted, showcasing all presentable items for Arçelik-Beko.

Real Refrigerator Design

The primary goal of the design was to create a unique and distinctive refrigerator. Various specifications were considered, but the team focused on selecting and executing the most logical ones. For instance, the interior organization of the refrigerator was carefully reconsidered based on the frequency of use, leading to the inclusion of a dedicated section for children, considering their role in shopping. Additionally, different colors and textures were experimented with on the refrigerator door.

The finalized specifications of the refrigerator include:

- Diversity of Colors

- Double Doors

- Door-in-Door feature

- Modularity

- Flexible Shelves

- Children’s Shelf

- Glass Front-Side

- Special Shelves for Drinks

- Special Food Cases

- Smart and User-Friendly Interface

- Easy Accessibility Door Handles

Conclusion

Throughout the design process, there were several mutual advantages shared between the authorities and the students. It proved to be an educative and creative experience for both sides, fostering collaboration and reinforcing the strong partnership between Anadolu University and Arcelik-Beko firm. The project contributed significantly to the correlation and synergy between the two entities.